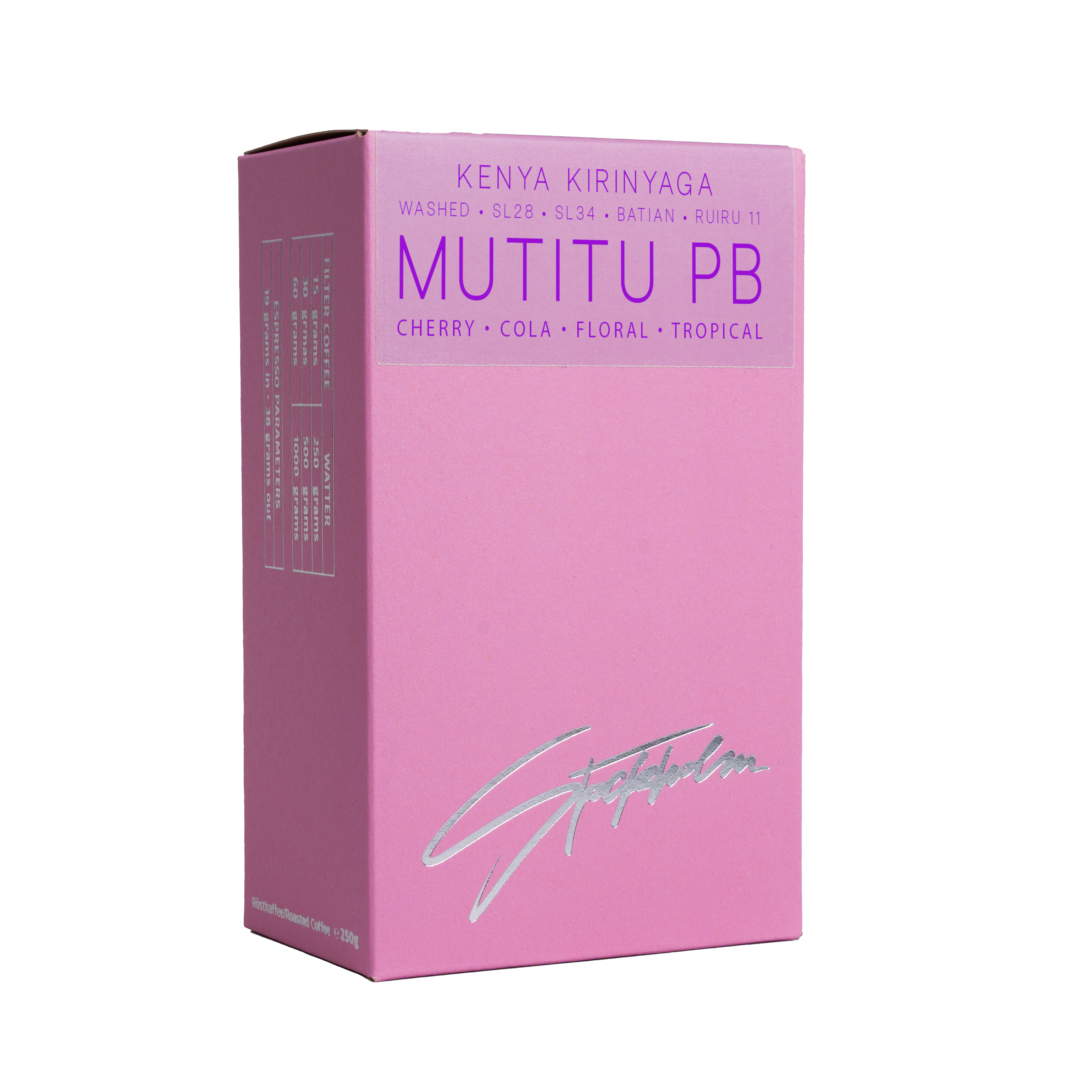

Kenya – Mutitu – Filter Coffee

17,90 € – 69,90 € Incl. VAT

Mutitu factory was started in 1963 and it lies on the southern slopes of Mount Kenya, in the Kirinyaga region. The mill is used by small-hold farmers in the area. This and the adjacent

regions are the premier coffee areas in Kenya, and the coffees from here are consistently among the best in the world.

Mutitu Kirinyaga

Farm: Mutitu

Region: Kirinyaga

Variety: Batian, SL28, SL34, Ruiru 11

Processing: Washed

Flavour notes: Cherry, Cola, Floral, Tropical

More Information:

Mutitu factory was started in 1963 and it lies on the southern slopes of Mount Kenya, in the Kirinyaga region. The mill is used by small-hold farmers in the area. This and the adjacent

regions are the premier coffee areas in Kenya, and the coffees from here are consistently among the best in the world

Mutitu factory is located in Kathekiini location, in Kirinyaga county. There are 1,250 members who deliver coffee cherries to the Mutitu factory who each have on average

around ½ acre of land with roughly 200 trees for coffee growing alongside macadamia, beans and corn.

In line with the rising awareness on the need to conserve the environment, the factory has dug the waste water soak pits away from the water source where the waste water is allowed to

soak in back to the soil. Additionally the society encourages its members to plant trees on their farms.

From our export partner:

The coffee is handpicked by the smallholder members and delivered to the factory where it is pulped. This initially separates the dense beans from the immature ‘mbuni’s (floaters) using

water floatation which means the denser beans will sink and be sent through channels to the fermentation tank.

This first stage of fermentation will last for around 24 hours, after which the beans are washed and sent to the secondary fermentation tank for another 12-24 hours. Once the fermentation

process is completed, the beans enter the washing channels where floaters are separated further and the dense beans are cleaned of mucilage.

The washed beans will then enter soaking tanks where they can sit under clean water for as long as another 24 hours. This soaking process allows amino acids and proteins in the cellular

structure of each bean to develop which results in higher levels of acidity and complex fruit flavors in the cup - it is thought that this process of soaking contributes to the flavour profiles

that Kenyan coffees are so famed for.

The beans are then transferred to the initial drying tables where they are laid in a thin layer to allow around 50% of the moisture to be quickly removed. This first stage of drying can last

around 6 hours before the beans are gathered and laid in thicker layers for the remaining 5-10 days of the drying period. The dry parchment coffee is then delivered to a private mill and put

into ‘bodegas’ to rest – these are raised cells made of chicken wire which allows the coffee to breathe fully. Coffee is traditionally sold through the country’s auction system, though recent

amendments to the coffee law of Kenya have brought about the introduction of direct trading whereby farmers can by-pass the auction and sell directly to specialty roasters around the

world.

Sourcing:

In Kenya, coffee is marketed through two primary systems: the Nairobi Coffee Exchange auction and direct sales, known as the "Second Window." Since its inception in the 1930s, the auction system has dominated the trade of Kenyan coffee, transitioning from traditional open-outcry bidding to a more subdued process, where traders activate electric triggers during bidding. This competitive environment often drives prices of sought-after coffees to remarkable heights.

Under the auction system, each estate or cooperative society partners with a marketing agent to present their coffees for bidding. These agents typically charge a commission ranging from 1.5% to 3% of the coffee price, in addition to government taxes. Auctions occur every Tuesday in Nairobi, with samples of the milled coffees available for inspection by interested bidders. Exporters frequently participate in the auctions, acquiring lots for private sales to importers and roasters.

The "Second Window" was introduced as an alternative avenue for farmers and buyers to negotiate prices independently of the auction. This process allows for pre- or mid-harvest discussions to agree on deals. Additionally, some exporters directly purchase coffees from marketing agents or mills, leveraging auction prices as a reference point.

-

Chose bag size:

1000g, 250g

You may also like…

Related products

-

2020 – Midsommar – Double Espresso – By – Carina Anderson

15,90 € Incl. VAT Read more -

AeroPress Clear

44,90 € Incl. VAT Add to cart -

Costa Rica – Finca San Cristobal – Filter Coffee

17,90 € – 69,90 € Incl. VAT Select options This product has multiple variants. The options may be chosen on the product page